|

FAQ

Frequently Asked Questions

Collapse All / Expand All

The first patent for an insulated tool was in 1907 by George E. Wood, who was already known for rubber removable tool coverings. Insulated tools are often used by electricians to protect themselves from electrocution, burns, and shocks. The plastic or rubber coating on insulated tools prevents the electrician from becoming a path to ground if the tool comes into contact with an energized conductor. Many tools today have a double layer of insulation to ensure backup protection.

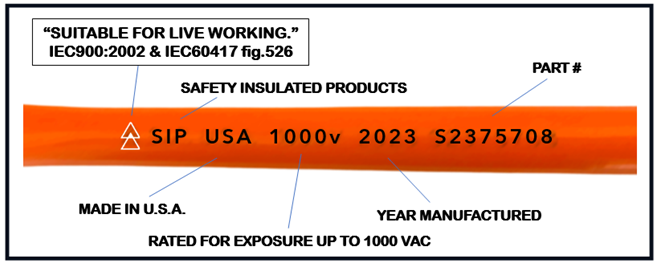

Insulated tools are made by dipping the tool in an insulation coating and curing it, or through injection molding. Insulated tools are tested at 10,000V and provide user protection for up to 1000V. Many tools must be certified by the ASTM F1505 and/or VDE, and must also bear the proper stamps of approval.

+

Why do I need insulated tools?

When working in close proximity to exposed energized equipment or working on live electrical circuits, it’s necessary to protect not only the worker but also the equipment that is being worked on. Rubber insulating gloves and insulated hand tools are vital components of a successful PPE system and should be used in conjunction with each other to provide maximum protection for the worker.

It's common to perform a task on de-energized equipment that is locked out and tagged out while still being within the shock boundary and in close proximity to other live equipment. In this case, a worker could accidentally lose control of a tool which could then make contact with live parts. If non-insulated hand tools were being used in this scenario it is very possible that a phase over could result and an arc flash would occur. Not only would the worker be exposed to injury, but the equipment in close vicinity to this would sustain serious damage resulting in costly repairs, replacement, or downtime.

Tools with plastic coatings or plastic handles are not suitable when “live” circuits are close to the task at hand. Employees should only consider the use of insulated tools that are marked with the official international 1000-volt for this type of work.

The double-triangle marking is the international symbol that identifies tools as safe for energized work. This symbol must be marked on all truly insulated hand tools. These insulated hand tools have a maximum use rating of 1000 VAC and must be dielectrically tested at 10,000 VAC, this equates to a safety margin factor of 10. These tools also meet or exceed current ASTM F1505-10 and IEC 900 Standards for Insulated Hand Tools and are necessary for compliance with the CSA Z462-12 Standards. While insulating hand tools are designed foremost to offer shock protection for the worker, they are considered secondary protection.

+

Why should I use insulated and isolated tools?

Why Should I Use Insulated and Isolated Tools?

"INSULATED/ISOLATED"

These tools are used to prevent electrical shock by providing a barrier between the user and live electrical components, with "insulated" referring to the material used to cover the conductive parts of the tool, and "isolated" indicating that the tool is designed to separate the user from the electrical circuit, effectively preventing current from flowing through the user's body if accidental contact occurs.

Key Points About Insulated and Isolated tools:

-

The primary reason to use these tools is to protect the user from electric shock when working on live electrical circuits.

Insulation Material:

This is the physical layer, like a rubber or plastic coating on the tool handle, that prevents electricity from passing through to the user.

Isolation Concept:

This refers to the design of the tool that creates a separation between the user and the electrical circuit, preventing direct contact with live components.

+

How do I clean and maintain my tools?

|

Maintenance

Use and maintenance of insulated tools are beyond the scope of the existing standards and specifications. You should use insulated tools for their intended applications only; for example, screwdrivers should not be used to pry or chisel. You should never modify or alter a tool from its original design. For instance, cutting back the insulation on a socket for use in tight spaces could in fact expose the worker to injury.

Because moisture, films, or other surface contaminants are conductive, insulated tools must be kept clean, dry, and free of any surface contaminants. The cleaning of insulated tools can be accomplished by using the same specialty concentrated detergent used to remove oils, grease and dirt from rubber insulated gloves. The important thing to remember when using cleaning agents is to ensure the agent does not contain any chemicals which may harm or lessen the protective value of the insulating coating. The ultimate goal is to get a residue free surface after cleaning and maintaining the insulation integrity of the tool.

Insulated hand tools should be stored properly to minimize the risk of damage to the insulation. Avoid storing in proximity to sources of heat such as radiators, furnaces, and steam pipes.

|

| |

|

Inspection

The barrier material used to produce insulating tools is impact-resistant and flame retardant and there is no re-certification process for insulated tools. Inspect all tools before use and discard tools that show any signs of visible damage. The ASTM F1505 standard allows for both single and double layer coatings. If double layer coatings are used, they should be of contrasting colors.

Overlapping two-color insulated tools make inspection easier which adds to overall safety. If the underlayer color is showing through the over layer color, the tool is no longer considered properly insulated and should be replaced. While there is no specific requirement in regard to color other than the layers being contrasting, the industry has adopted the use of orange for the outer layer and yellow for the inner layer for all-purpose tools. Most manufacturers producing double layer insulated tools follow this color pattern thus allowing the inner layer to be seen during the tool inspection process. Note that specialty tools made from Aluminum-Bronze and Copper-Beryllium alloys that are non-sparking and non-magnetic and are insulated will also have a color-contrasting double layer coating. To differentiate from all-purpose tools, these specialty tools use another color for the outer insulating layer.

For safety reasons other than shock and arc flash hazards, it is recommended that appropriate eye and hand protection be worn when using any type of hand tool. To fully comply with the CSA Z462-15 standard, truly insulated hand tools should be used if there is any chance that the tool will make contact with an energized source. A complete insulated tool program meeting these standards is achievable; you simply need to ensure that all your tools meet the ASTM F1505 and/or IEC 60903 standards for insulated hand tools.

Contributed by: Roger Farmer, Salisbury by Honeywell

|

+

Do you ship internationally?

| We ship internationally. Due to varying taxes, duties, and fees per country, we use the customer's UPS or FedEx account for shipping. Additionally, most international customers will need to pay with a wire transfer to our account. |

+

Do you have a Privacy Policy?

Privacy Policy for 1000vtools.com

Effective Date: January 1, 2025

At 1000vtools, LLC (www.1000vtools.com) we value your privacy and are committed to protecting your personal information. This Privacy Policy outlines the types of personal information we collect, how it is used, and the steps we take to ensure your data is handled securely.

1. Information We Collect We collect personal information when you interact with our website or contact us via email. The types of information we may collect include:

- Personal Identification Information: This may include your name, email address, phone number, and any other information you provide when contacting us or signing up for newsletters, promotions, or other services.

- Non-Personal Identification Information: This includes browsing information such as IP address, browser type, device type, and website usage patterns. This information is collected automatically through cookies and other tracking technologies.

2. How We Use Your Information We use the information we collect for the following purposes:

- To respond to your inquiries and requests via email or contact forms.

- To improve our website and user experience by analyzing usage data.

- To send newsletters, promotional offers, or updates about our products and services, provided you have opted in to receive such communications.

- To comply with legal obligations and protect the rights, property, and safety of our business, customers, and website users.

3. Data Protection and Security We take appropriate security measures to protect your personal data from unauthorized access, alteration, or disclosure. However, please be aware that no data transmission over the internet is 100% secure. While we strive to protect your personal information, we cannot guarantee its absolute security.

4. Sharing Your Information We do not sell, rent, or trade your personal information to third parties. However, we may share your information in the following circumstances:

- With trusted service providers or partners who help us operate our website or conduct our business, such as email marketing platforms or website analytics services.

- When required by law, regulation, or legal process, such as responding to a subpoena or court order.

- To protect the rights, property, or safety of 1000vtools.com, our customers, or others.

5. Cookies and Tracking Technologies Our website uses cookies and similar technologies to improve user experience, personalize content, and analyze website traffic. You may adjust your browser settings to refuse cookies, but this may affect the functionality of our website.

6. Your Rights and Choices You have the right to access, correct, or delete your personal information. You can also opt out of receiving marketing communications from us by following the unsubscribe instructions in our emails.

If you would like to exercise any of your rights or have questions about your personal data, please contact us at [michael@1000vtools.com].

7. Links to Third-Party Websites Our website may contain links to third-party websites. We are not responsible for the privacy practices or content of those websites. Please review their privacy policies before providing any personal information to them.

8. Changes to This Privacy Policy We reserve the right to update or modify this Privacy Policy at any time. Any changes will be posted on this page, and the effective date will be updated accordingly. We encourage you to review this Privacy Policy periodically for any updates.

9. Contact Us If you have any questions or concerns about this Privacy Policy or how we handle your personal information, please contact us at:

Email: michael@1000vtools.com

Website: www.1000vtools.com

+

How do I care for a torque wrench?

7 TIPS ON HOW TO USE A TORQUE WRENCH

Used with Permission Chicago Pneumatics

What is a torque wrench?

A torque wrench is a tool used to control and apply a specific torque to a fastener such as a bolt or a nut. It is a fundamental element in general mechanics, tire-changing operations, and industrial maintenance & repair industries to ensure customers' safety.

Each vehicle type has different torque specifications, set by the manufacturer, which must be respected when servicing the vehicle. Not only for the wheels but also for any other bolted parts such as the cylinder head, a torque-controlled solution must be used to tighten at the required torque.

How to use a torque wrench:

- A torque wrench is a tightening tool. It is a very sensitive and precise tightening tool and should never been used to loosen bolts.

- Handle your torque wrench as carefully as you treat a measurement instrument! The tool should always be stored in its storage box and protected from any shock.

- At the end of each day, or when it is not used, the torque wrench should be reset to the lowest value, to release the string pressure.

- Only use one hand with a fluent and continuous move. Most of the torque wrenches have a mark on the handle, this is to indicate where to apply pressure.

- Do not use an extension on the handle. This would impair the set value in being correctly signaled.

- A torque wrench prevents but does not avoid over-tightening! When the required torque is reached, the torque control system of the wrench will be "activated", and the operator will hear a clear click sound. If you hear this "click" without moving the wrench at first, it means that the application has already been over-tightened. The good practice here is to start over: Loosen the bolt first, tighten it with an adapted tool, and finish with the torque wrench to reach the correct and safe torque.

- Tool Maintenance: As a high-precision tool, a torque wrench needs to be re-calibrated on a regular frequency, and it's the tool's user responsibility. Depending on use, we recommend a minimum of yearly tool re-calibration, or every 5000 cycles, Contact us for our in-house re-calibration service. Not to mention that if the tool has been dropped or damaged, it must be sent to service immediately.

** Some Images are Enlarged to Show Details **

For More Information Contact:

or

Proper safety equipment (PPE) must be worn while working on or near live power.

Return Policy:

Items returned within 2 weeks of the sale in good sellable condition* will be given a merchandise credit less a 25% re-stocking fee. Freight will not be credited. Items returned after 2 week period of sale will not be given credit.

Due to fluctuating market prices for tools and shipping, website prices are subject to change without notice.

|